Plastic gears can also be used industrially; they are found in processes within automotive manufacturing, marine manufacturing, aerospace components manufacturing and many other industries. These gears are generally very cost effective and lightweight. Read More…

For 50 years, LTM Plastics has been a leading manufacturer of injection molded plastics. When working with LTM Plastics, our customers can be assured that they are getting high quality products at a competitive price. We pride ourselves on our team’s communication and collaboration with our customers to meet their needs.

If you are in need of injection molded plastic parts that are of consistent quality, look no further than MSI Mold! We have over 30 years of experience in design, production, and tooling of custom plastic parts.

Performance Engineered Products, Inc. is a dynamic and innovative company, and we pride ourselves on being at the forefront of the injection molded plastics industry. With a rich history dating back to 1981, we have consistently demonstrated our commitment to excellence in both products and services.

We may have started small, but today, we offer our products and services to companies around the world. We are dedicated to our customers, and our goal is to offer better service and pricing to any customer no matter the size.

Hi-Rel Plastics & Molding, Inc. offers injection molding for a variety of industries. We can process an almost infinite variety of thermoplastic resins, our prices are competitive, our delivery is on time, and we provide superior customer service. Value-added services include label application, assembly services, and custom packaging and shipping. Our team has the knowledge and expertise to...

As one of the Midwest’s oldest plastic molders, Koller-Craft has craftsmanship built into its name. We take pride in our quality injection molding work. Large to small parts, short to long runs. Excelling at product design, prototyping, close tolerance molding, insert molding & secondary services.

A leader in the plastic processing industry for over 70 years, Aptyx provides a range of manufacturing services including injection, blow and dip molding, extrusion, and assembly. Within injection molding we are deeply experienced in complex processes such as over molding, two-shot molding and insert molding. With a focus on delivering high-quality product and exceptional customer service, you...

Valencia Plastics is your leading full-service injection molded plastics manufacturer. Our products are made with various materials, including urethane, polyurethane, nylon, acrylic, and polycarbonate. We offer a wide range of sizes from miniature items up to 7 lbs. large parts. We are ISO 9001:2015 compliant. Industries we serve include electrical, military, automotive, aerospace, and...

Abtec, Inc. is a manufacturer of injection molded thermoplastics for high-tech OEMs. Since 1981, we have provided quality injection molded plastics and engineering services to such industries as automotive, aerospace, dental, electronics, food handling, nuclear, reprographics and more. Our 21,000 square feet building operates 24-hours a day, 5 days a week. Contact us today!

You won’t find better quality injection molded plastics anywhere else in the industry. We have built ourselves up from a small manufacturing company to a large company with decades of experience.

More Plastic Gear Companies

Types of Plastic Gears

Plastic Spur Gears

Spur gears are the most common gears, and one can easily identify them by the teeth that stick out from the edge. Their teeth line up with the shaft axis in a straight line.

Plastic Helical Gears

Unlike spur gears, which have teeth that are parallel to the shaft, these gear types feature teeth that are placed at an angle. This causes more teeth to come into contact with each other during the procedure. More weight may be carried by plastic helical gears than by plastic spur gears. The teeth of plastic helical gears can distribute the load. In turn, this configuration enables plastic helical gears to function more quietly and smoothly than spur gears. Plastic helical gears provide a thrust force during operation that must be taken into account while using them. Most enclosed gear drives use plastic helical gears.

Plastic Herringbone Gears

These gears resemble twin helical gears; however, they don't have a space between their helical faces. Herringbone gears are typically smaller than double helical gears. They are thus perfectly suited for situations involving significant stress and vibration. These gears are not frequently utilized since they are expensive to produce and have manufacturing issues.

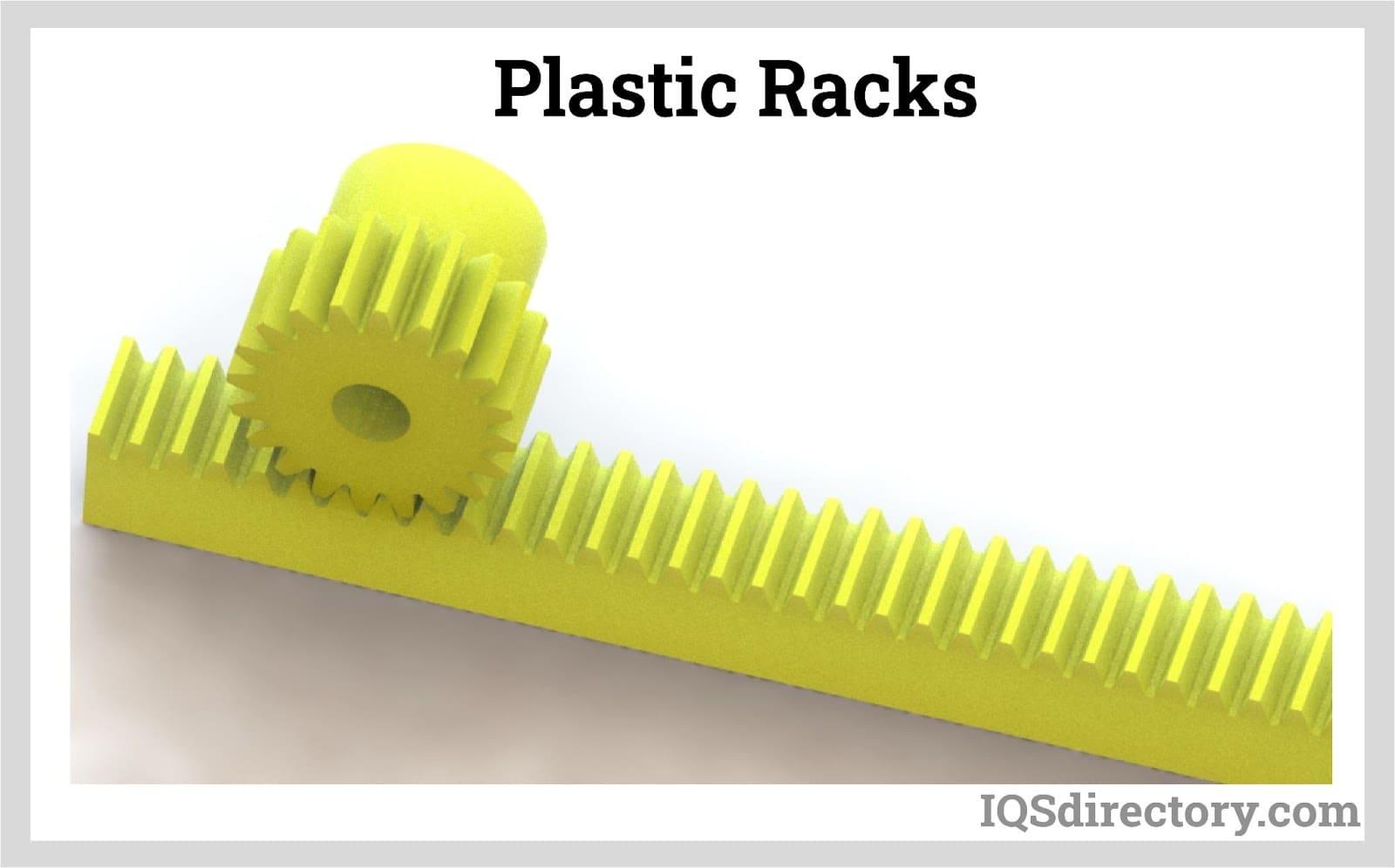

Plastic Pinion and Rack

The main applications of a rack and pinion are the transformation of linear movement into a circular pattern and vice versa. When the pinion is rotated, the rack is driven in a straight path. On the other hand, the pinion will rotate if the rack is shifted linearly.

Plastic Bevel Gears

This kind of gear features spiral or straight-cut teeth and a conical form. Plastic bevel gears change the rotation axis by transferring motion between two intersecting axles. Typically, power equipment and automotive applications use these kinds of gears. The spiral-cut version can generally be quieter and smoother than other versions on all designs.

Plastic Worm Gears

These cylindrical plastic worm gears mesh with another gear to turn it. They have an exterior spiral thread. In this particular gear arrangement, a worm or a screw strikes a gear. Worm gears can be used to boost torque in a variety of sectors. They are used when considerable gear reductions are necessary. Worm gear reductions usually range from 20:1 to 300:1 or higher. The self-locking feature typically found in plastic worm gears allows the worm to turn the gear but not the other way around. The shallow angle of the worm prevents it from spinning when the gear tries to turn it because of friction. High-speed reduction gearing commonly employs plastic worm gears.

Applications of Plastic Gears

- Automobiles: For many years, researchers have concentrated on developing the materials used in gears to address several issues, including gear teeth breaking at the root due to fatigue, teeth wearing down at the flank, localized overheating, excessive noise, shock loading or hard stops, and noise vibration problems. Plastic gears are being employed to reduce such issues.

- Drone: Due to their light weight, plastic gears are used in drone technologies to drive the wings of the drone.

- Prototyping: Plastic gears can be cast in very small sizes, which allows them to be used by different engineers in prototyping their designs.

- Printing Technology: Most printers use plastic gears for their motion. This is because printers require dry material and plastic gears are self-lubricating.

- Manufacturing Industries: Because of their tooth bending and load-sharing abilities, plastic gears are used in the production of several components because they can support the higher weight. Bending stress may attempt to bend the gear's teeth and tear them away from the bulk gear material. These forces result in static stress and fatigue, which ultimately lead to tooth-breaking failures. Plastic gear teeth, however, distribute the strain over a greater number of teeth by deflecting more when loaded. The load-bearing capability of the plastic gears is increased by their load-sharing capacity.

Benefits of Plastic Gears

- Cost-effectiveness: Making plastic gears is typically less expensive than making metal gears. Plastic gears are often 50% to 90% less expensive than metal gears because they don't need any further finishing.

- Molding Design Flexibility: Compared to metal, plastic molding enables a wider range of effective gear designs. For creating forms like internal gears, worm gears, and cluster gears, where the cost of production in metal can be prohibitive, molding is the best method.

- Accuracy of Plastic Gears: Plastic gears are capable of achieving great levels of accuracy. Consistent material quality and precise molding process control can accomplish this.

- Corrosion Resistance: Unlike metal gears, plastic gears are unaffected by corrosion. Due to their relative inertness, they can be employed in water meters and chemical plant controls. They can also be applied in any other situations where metal gears might rust or lose their quality.

- Light Weight: Plastic gears weigh less than metal gears of the same size.

- Good Shock Absorption: Compared to metal gears, plastic gears can deflect to absorb shock stresses. Localized loads that cause tooth faults and misalignment are likewise distributed by plastic gears.

- Reduced Noise: Due to the noise-dampening characteristics of plastics, plastic gears produce a quiet operating gear by reducing noise levels. Due to the need for highly precise tooth shapes and flexible materials for quieter drives, plastics are necessary.

- No Lubrication Needed: Plastic gears are naturally lubricious, which makes them perfect for printers, toys, and other low-load, dry gear applications.

Selecting the Right Plastic Gear Manufacturer

To ensure you have the most positive outcome when purchasing plastic gears from a plastic gear manufacturer, it is important to compare several plastic gear manufacturers using our directory of plastic gear manufacturers. Each plastic gear manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each plastic gear business website using our proprietary website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services